When you think of the cars we drive every day- sleek electric vehicles, family SUVs, or heavy-duty trucks- you likely imagine innovation, power, and freedom. But behind every smooth ride is a rigorous process that ensures the car you’re driving is safe, reliable, and compliant with international standards. That’s where automotive quality control plays a crucial role.

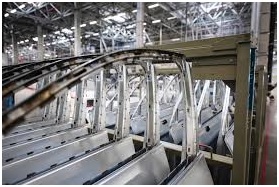

The global auto industry is massive and complex. Cars are not made in one place but assembled using parts from hundreds of suppliers spread across different regions. To ensure every part meets safety regulations and functions as intended, there needs to be a thorough system of checks at every step- from design to production to the final inspection. This system is what we call automotive quality control.

Let’s take a closer look at how this process works, why it’s essential, and what companies can do to avoid the risks of poor quality.

The Growing Need for Quality in the Auto Industry

Modern vehicles are far more than just machines. They are advanced pieces of technology with integrated electronics, sensors, software systems, and hundreds of mechanical parts. A minor flaw in one component- whether a brake system or airbag sensor- can result in product recalls, accidents, or legal action.

Consumer expectations have also risen. Buyers want more than just fuel efficiency or design; they demand performance, comfort, and above all, safety. This makes automotive quality control more important than ever.

Key Areas of Automotive Quality Control

Quality control in the auto industry isn’t just about the final inspection. It starts much earlier in the production cycle and includes multiple levels of evaluation:

1. Incoming Material Inspection

Before parts go into production, raw materials and components from suppliers must be inspected. This ensures they meet the required specifications, tolerance levels, and safety standards.

2. In-Process Quality Control

During the assembly of vehicles, manufacturers conduct ongoing checks to ensure machines, labor, and tools are working within defined standards. These checks help in catching defects early in the process.

3. Final Product Inspection

This is where the vehicle is tested after complete assembly. Braking systems, emissions, lights, steering, and even paint quality are thoroughly evaluated before shipment.

4. Random Audits and Stress Testing

Cars may also go through real-world simulations and environmental testing- cold starts, crash tests, and rough terrain performance- to assess their behavior under extreme conditions.

How Quality Control Reduces Recall Risks

Vehicle recalls are not just costly- they’re brand killers. Just one defective batch of engines or faulty seatbelt latches can cause millions of dollars in losses and tarnish a company’s reputation.

Robust quality control systems aim to catch problems early, well before they reach customers. These systems include:

- Statistical Process Control (SPC) to track variations during production.

- Failure Mode and Effects Analysis (FMEA) to evaluate potential weaknesses in the design.

- Corrective and Preventive Action (CAPA) to ensure future issues don’t repeat.

In short, the cost of quality control is far less than the cost of a large-scale recall.

Role of Factory Audits in the Automotive Supply Chain

Automakers often work with hundreds of parts suppliers, many of whom are based in countries like China, India, or Eastern Europe. Ensuring that these suppliers meet international safety and quality norms is a major challenge.

That’s why many manufacturers invest in a Factory Audit process before forming long-term relationships. These audits help companies evaluate:

- The supplier’s manufacturing capability

- Quality control procedures in place

- Compliance with ISO standards

- Employee qualifications and safety measures

An audit doesn’t just reduce risks- it also provides transparency and confidence in the supply chain.

Common Automotive Quality Defects and Their Impact

Some of the most common quality issues found in the automotive industry include:

- Faulty wiring or electrical malfunctions

- Engine oil leaks

- Cracked windshields or body frame defects

- Faulty airbags or seat belts

- Brake fluid leakage or reduced braking efficiency

These issues can go unnoticed without proper inspection procedures. In some cases, undetected defects can lead to life-threatening accidents. That’s why automakers spend millions of dollars annually on advanced quality assurance technology, employee training, and safety compliance.

Compliance with Global Regulations

Every region has its own automobile regulations. For example:

- The U.S. follows standards set by the National Highway Traffic Safety Administration (NHTSA).

- Europe adheres to guidelines under the Economic Commission for Europe (ECE).

- China has its own regulatory framework with performance-based rules.

Failing to comply with these standards can stop a vehicle from being sold in certain regions. Companies must stay up to date with international compliance requirements, conduct regular audits, and maintain proper documentation.

This is where a reliable third-party inspection partner becomes essential. With neutral expertise, these inspectors ensure that both components and finished vehicles meet quality and regulatory standards without any internal bias. A trusted third-party inspection agency can catch non-compliance before it becomes a legal or logistical nightmare.

The Future of Automotive Quality Control

Technology is revolutionizing every aspect of auto manufacturing- including quality control. Here are some trends shaping the future:

- Artificial Intelligence (AI): AI-powered cameras and sensors detect visual defects faster than human inspectors.

- Predictive Maintenance: IoT sensors can predict failures before they happen.

- Digital Twin Technology: Real-time simulations of physical products to spot flaws during virtual production.

As the world moves towards autonomous and electric vehicles, the complexity of quality control will only increase. This means the processes must be smarter, faster, and more adaptable.

Final Thoughts

Automotive quality control is no longer optional; it is a core part of delivering safe and reliable vehicles to customers. From checking raw materials to conducting full vehicle inspections, each step is crucial in ensuring that the final product meets global safety and performance standards.

By investing in robust inspection systems, embracing new technologies, and conducting regular Factory Audit checks, manufacturers can maintain customer trust, reduce risks, and stay ahead in the competitive auto industry.

In the end, quality control isn’t just about protecting the car. It’s about protecting the people who drive it.